Factors affecting rock strength

There are many factors that affect rock strength:

1. Mineral composition The mineral composition of rocks has a direct impact on the physical and mechanical properties of rocks, such as quartzite with a high quartz content, which is stronger than marble with a high calcite content.

2. Structure Common structures include rocks connected by crystals and rocks connected by cements. The size of crystal particles and the form of cementation have an important impact on rock strength.

3. Structure Mainly refers to the uneven distribution of mineral components in rocks and the discontinuity of rock structures, such as flaky structures, plate structures, and phylloxetine structures.

4. Water The strength of rocks is reduced after being saturated with water. The greater the porosity of the rock, the more obvious the softening property of water.

5. Weathering Weathering causes the original cracks in the rock to expand further and produces new weathering cracks, loosening the connection between rock mineral particles and causing mineral particles to collapse along the cleavage plane.

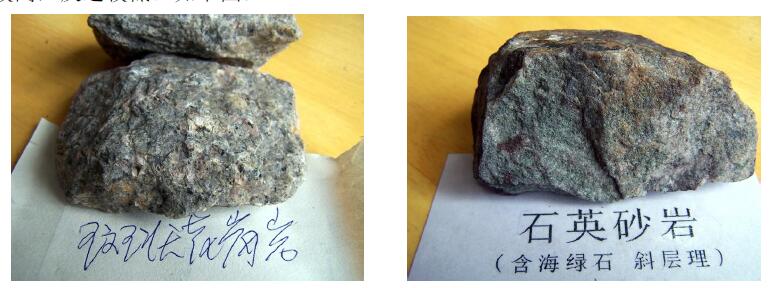

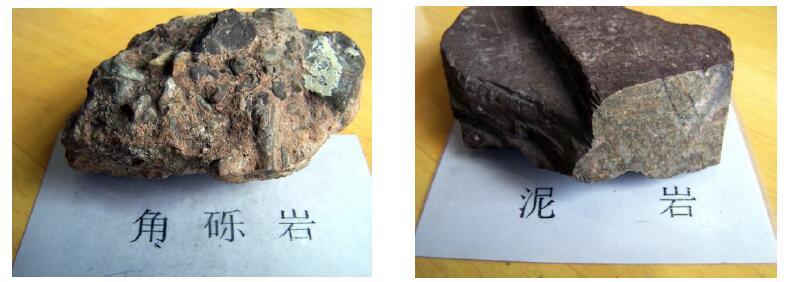

Therefore, it can be seen from the above influencing factors: the proportion of hard minerals such as quartz, feldspar, and amphibole is high; fine-grained crystals or calcium and siliceous cementation; blocky structure and uniform distribution of minerals; rock with low weathering degree and water content has higher strength, and vice versa. As shown in the following figure:

Figure 1 Crystal structure, high content of quartz and feldspar (hard rock)

Figure 2 High quartz content (hard rock)

Figure 3 Large particles and loose structure (soft rock)

Figure 4 Clay minerals (soft rock)

Hard rock drilling characteristics

Hard rock drilling characteristics include: rock drillability, drilling speed and efficiency, hole wall stability, drilling cost and other aspects. These indicators are analyzed in detail below.

Drillability: Hard rock is difficult to drill due to its high strength and hardness. In addition, the drillability of rock has a great relationship with its weathering degree, mineral composition, and structural structure.

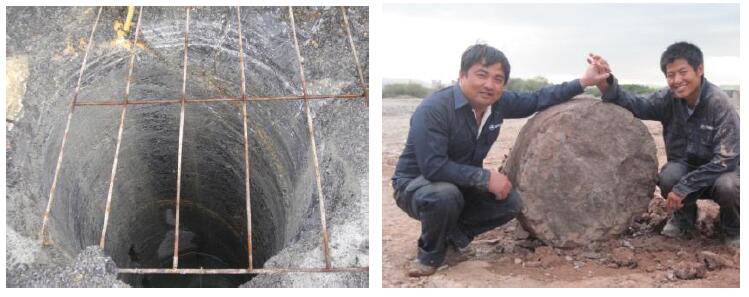

Drilling speed and efficiency: In highly weathered rock formations, for example, with a pile diameter of 1 meter, the rotary drilling speed is approximately 0.5 to 2 m/h. For moderately weathered rock formations, the drilling speed is approximately 0.25 to 0.5 m/h.

Hole wall stability: The rock formation has good stability, the borehole wall is stable, and there is generally no hole collapse or peeling in the rock formation wall section.

Drilling cost: The rock formation has a slow drilling speed and high fuel consumption. In addition, the drill teeth are severely worn, and the drill rod and drilling rig failure rate is higher than other formations, so the drilling cost is also the highest among all formations.

Common hard rocks in rotary drilling construction include granite, calcareous sandstone, limestone and other formations. The drilling difficulty of hard rock formations is high, the efficiency is low, and the equipment configuration and operation method are required to be high. Therefore, the research on the technology of rotary drilling rigs is of great significance.

Figures 5 and 6 below are photos of limestone drilling and quartz sandstone coring.

Contact: Sunmoy

Tel: + 86 15888243000

Whatsapp: + 86 15888243000

Email: sunmoy@sunmoy.com

Add: DACAO INDUSTRIAL ZONE,DEZHOU,SHANDONG,CHINA